trial by fire

I should have been a painter. I can paint, you know. The bonus, there’s no need to set the thing on fire to see if it will survive. I miss painting…or maybe it is that I just miss the intoxicating aroma of linseed oil with a touch of turpentine.

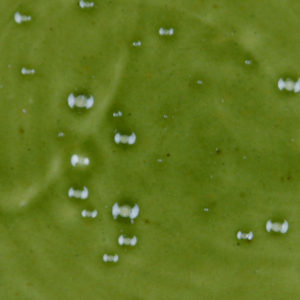

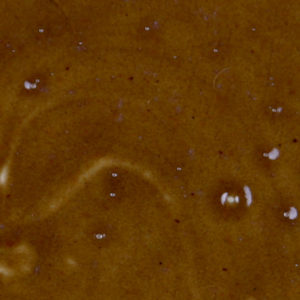

I’d like to blame that —————————->

on the person who fired the kiln! If the work doesn’t end up as expected, it’s certainly the fault of the person firing. After all, that’s the only part of the process in which you have little control. Not your fault!!

Though it is true that a poorly managed firing can destroy a lot of work, it’s also true that it does so without respect to any work. Usually you’ll lose much of the load. In this situation, I have only three pieces behaving badly in the entire load; which reasons that the problem wasn’t the firing. I’m off the hook! (said the person that fired the kiln)

I can assume raw materials aren’t the cause of the glaze issue because, again there isn’t general misbehavior with the same glaze on other pieces. Only these three – two green and one brown. So then, I can’t point to the person making the glazes. (um…me again)

In the spirit of full disclosure, the green and brown are the same base glaze. The green has been known to fuss on occasion. But, the brown has always been (until now) my stoic, reliable friend.

That leaves the process of getting the glaze on the surface. Glaze application issues aren’t generalized throughout an entire kiln load except when a person hasn’t been taught appropriate application. In which case, every piece loaded in the kiln is a test with the hope for a happy accident. Only the pieces you screw up will be screwed up. The rest will be wonderfully predictable. (you have to work very hard to get to predictable)

There are several variables to consider and not all are worth considering. This kiln load was glazed over the course of a couple weeks; in between preparing for an exhibition. There were a few wet, rainy days, so additional moisture (or slow evaporation) could have played into the application process. There was also a goodly amount of saw dust about the studio. (I do attempt to keep the place tidy. But, for cryin’ out loud, I’m only one person) Free organics on the raw glaze surface might provide an easy scapegoat. Eh…I’m pretty sure that burned off early. I always rinse the bisque before glazing, so I don’t believe there was anything trapped between the bisque and the glaze. I can reasonably tell that the pin holing occurred earlier in the firing process…OK. Maybe. Perhaps, unintended organics contributed to this problem.

There are several variables to consider and not all are worth considering. This kiln load was glazed over the course of a couple weeks; in between preparing for an exhibition. There were a few wet, rainy days, so additional moisture (or slow evaporation) could have played into the application process. There was also a goodly amount of saw dust about the studio. (I do attempt to keep the place tidy. But, for cryin’ out loud, I’m only one person) Free organics on the raw glaze surface might provide an easy scapegoat. Eh…I’m pretty sure that burned off early. I always rinse the bisque before glazing, so I don’t believe there was anything trapped between the bisque and the glaze. I can reasonably tell that the pin holing occurred earlier in the firing process…OK. Maybe. Perhaps, unintended organics contributed to this problem.

I might continue to speculate. But, in the end, I only have three pin holed plates from an entire kiln load for the shard pile. (I take full responsibility for the shard pile)

I might continue to speculate. But, in the end, I only have three pin holed plates from an entire kiln load for the shard pile. (I take full responsibility for the shard pile)

**just updated the Clay Drawings tab with work from exhibition at Central Arizona College.